|

|

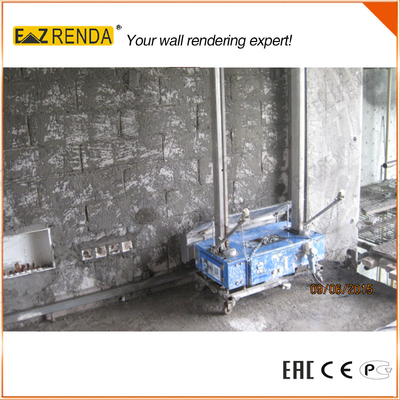

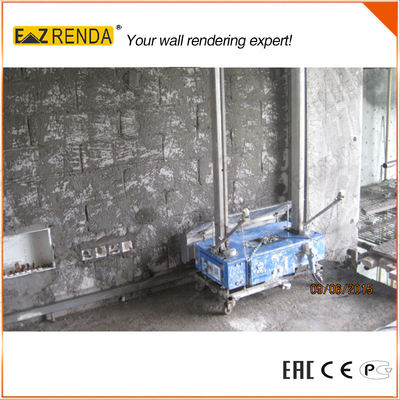

70 - 80 sqm/hour effeciency concrete block rendering machine

|

جزئیات محصول:

پرداخت:

|

| Model NO: | EZ-XP-4.0 | Dimension: | 1150*700*500mm |

|---|---|---|---|

| Control: | Remote Controller (Special Design) , Button Control ( Normal ) | Smoothing Knife: | inclusive |

| HS Code: | 8474310000 | Material: | Stainless Steel 304 |

| برجسته کردن: | ,,wall render machine |

||

70 - 80 sqm/hour effeciency concrete block rendering machine

Quick Details

- Condition: New

- Automatic Grade: Automatic

- Power(W): 0.75 KW

- Rendering Thickness: 4-30 mm

- Rendering Height: 4.2 m

- Place of Origin: Guangdong, China (Mainland)

- Brand Name: EZ RENDA

- Model Number: EZ-XP-4.0

- Dimension(L*W*H): 1150*700*500 MM

- Weight: 100 KGS

- Certification: CE,GOST,PATENT,TC-RU

- Warranty: 1 Year

- After-sales Service Provided: Engineers available to service machinery overseas

- Electricity Phase: Single Phase

- Rendering Speed: 70 - 80 sqm/hour

- Length of Plastering Trowel: 1000 MM

- Power System:Stable Hydraulic System

Description:

XP-4.0 (auto) is unique machinery designed for wall rendering. Its automation instead of manual wall rendering and the professional finishing clears your worries behind. Compare with XP-3.0, there are outstanding characteristics summarized as follows:

The new driven system enable output of main power is more peaceful and stable.

The light material enable machine is more portable.

The new lifting installation instead of traditional wire rope, enable the main moves easier and smoother

Far more easily operating! Longer lifespan than evermore!

Automatic leveling system enables higher speed.

Application:

brick wall, block wall, internal wall, external wall,, house, building, construction ,all indoor wall with ceiling can use for

The materials for machine plastering: cement mortar,ready mix mortar, gypsum mortar,lime mortar.

Advantage:

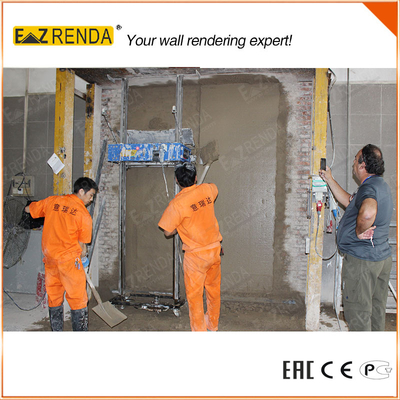

1. Once coating: escape from boring and repeating manual rendering

2. Professional finishing: smooth and flat mirror finishing in horizontal and vertical level

3. Quite suitable to render bathroom, corridor, apartment, house and villa, etc

4. Reach the ceiling completely without 1mm empty space remaining

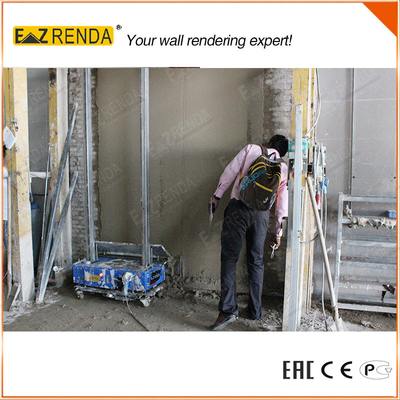

5. Easy to move with 360 degree angle wheels

6. Flexible render thickness 4mm-30mm

FAQ:

1- Q: Whether the machine could be used for the external wall and ceiling?

A: No, it couldn’t at present. We are still working on it. It will coming soon!

2- Q:Whether the hollow and cracking could happen?

A: Hollows can be avoided because there are three vibrators behind the mortar tank.

It creats high pressure to the wall when machine works. And watering before rendering the wall can avoid cracking.

3- Q:How about the finishing effect? Whether it is smooth?

A:The finishing effect is definitely smooth, no hollow, no cracking. The difference is less than 2mm.

4-Q:How many people need to operate the machine effectively? What is their division of labor?

A:Normally 3 people are enough to operate the machine, two people operate the machine and one person is in charge of small area repairing.

5-Q:How do we use the machine on walls with openings such as windows and doors? Can it be done with the machine or do we have to do it manually?

A: All models of machines can definitely render the area which is below and above window.

For the machine VISTA and XP: Supply little mortar at first, when the machine reach the open area, the mortar is nearly used up. After the machine passed the open area, press the “STOP” button and supply the mortar to render the top area then.

6- Q:How is the machine cleaned after use?

A:After finish using the rendering machine, the cleaning job needed to be done after the power is cut off.

Use water to wash the caster, plastering tank, directional pipes, extensions. The machine body and the buttons could only be cleaned by the cloth.

7- Q:What is the life for the m/c?

A: 3-5 years at normal use

8- Q:What maintenance is required at site?

A:

- Clean the machine each time after finishing using.

- Oil mechanic parts daily and grease every week;

- Change gear box oil(18#gear oil with 350ml) every 3 months;

- Check each part of the machine and replace wearing parts regularly;

- Check wire rope daily and replace no more than one month. (VISTA);

- Add the hydraulic oil when needed.

![]()

![]()

![]()

تماس با شخص: Ms. Angel

تلفن: 86-18665624699